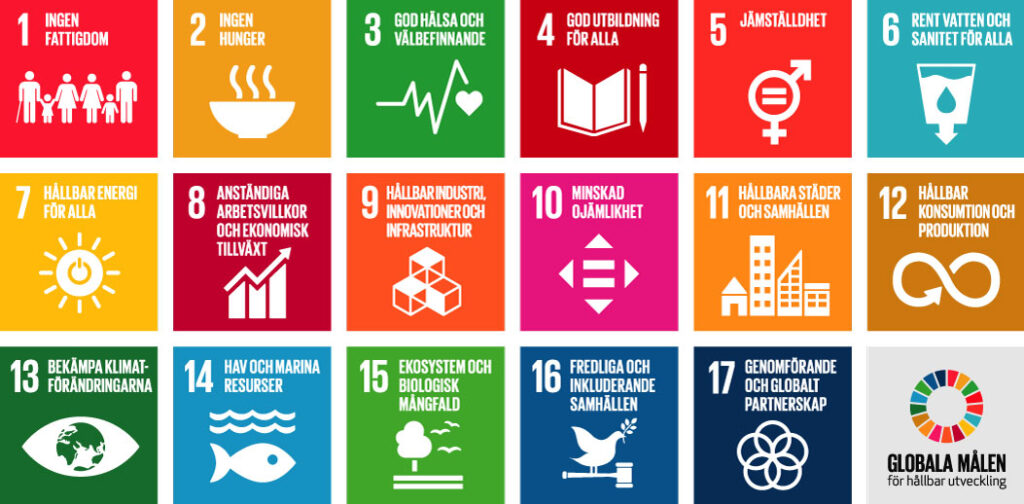

Our sustainability work is based on the UN’s 17 Global Goals, where we prioritise Goal 12. Goal 12 focuses on enabling more sustainable consumption and production patterns. We see that we can broadly and deeply make a difference within this goal by reducing the climate impact throughout the value chain. This important work involves a combination of internal efforts and collaborations with customers and partners. Everything is connected, just like the Global Goals.

More climate-smart pumping stations through ash in the cement

Uniwater has identified areas for climate work based on the business, where the ability to influence is greatest. Here, for example, Uniwater is working on the procurement of cement and steel – two materials that cause relatively high carbon dioxide emissions during production. Efforts to limit emissions can, therefore, make a big difference.

“We benefit from working with suppliers that also have ambitious climate goals, such as Cementa, which has an internal goal of being climate-neutral by 2030. This means net zero carbon dioxide emissions during the lifetime of the cement product,” says Therese.

Adaptation to climate change throughout the chain

Uniwater’s climate work is based on global, European and Swedish targets, as well as customers’ supplier requirements. Procurement requirements, regulations and technical capabilities are changing and require continuous improvement efforts.

“At Uniwater, we are firmly committed to reducing our carbon footprint in line with the latest climate research. We are working on internal improvements in the climate area. For example, we have switched to fossil-free energy in all group companies. We have also updated our group-wide vehicle policy with emission requirements. This policy will be reviewed and adjusted over time,” says Therese Löwenberg, Quality and Sustainability Manager at Uniwater.

Norvatek is the Uniwater company that purchases the largest volumes of cement for use in the construction of pumping stations. They have previously used construction cement but have now started tests with the so-called construction cement FA from Cementa.

“Emissions can be significantly reduced by supplementing cement with fly ash, which is an energy production process using coal. Calculations show that carbon dioxide emissions are reduced by about 20 per cent per tonne of cement produced compared to conventional construction cement. Tests are currently being carried out at Norvatek. The goal is to switch to construction cement FA during the first quarter of 2023, which feels very positive,” says Therese.

Suppliers that inspire

Another example of climate pioneering suppliers is the Portuguese company Fucoli, a manufacturer of water infrastructure products with which Uniwater’s subsidiary Ibeco works closely. Fucoli only uses green electricity and recycled steel that they collect locally in their production.

“The steel purchased by Uniwater companies is mainly steel used for wells and concrete product reinforcements for pumping stations. We choose steel that contains a high proportion of recycled material and most of the steel, around 80 per cent, comes from Europe. Currently, we cannot obtain certain pipe dimensions in Europe, but we are working towards the goal of further increasing the proportion of steel coming from the local area,” says Therese.